Matrix and the Indoor Cycling Group (ICG®) debuted their new IC7 Indoor Cycle with power at IHRSA last month. In many respects it's different from any group cycle on the market today. You could go so far as describing a number of their technical innovations as revolutionary - not to mention how everything is wrapped in a very good looking package.

Where do I even start?

There are so many innovations engineered into the IC7, it's difficult to know where to begin... So I'll list off a bunch of the cool features that I feel are important and IMO not just marketing hype. You can download an informative brochure for the IC7 here.

First the basics

The IC7 features a unique two-stage, belt driven drivetrain - a toothed belt so it retains the feel of a chain. Turning away from the friction pads and weighted flywheel on their previous models, the IC7 now spins an aluminum flywheel and utilizes magnetic resistance, controlled by a micro adjusting knob with 100 (yes you read the correctly) individual levels to choose from.

If Q-Factor is important to you, it now appears that the IC7 is now the narrowest on the market @ 155mm - three millimeters narrower than the claimed 158mm of the Blade Ion. Just for fun, I measured my VeloVie road bike, with its top of the line SRAM Red Groupo @ 149mm. FYI - Spring is here and our member's discount on a new VeloVie bicycle is waiting for you here.

Fitting the IC7 to various size riders is done with seat/handlebar gas strut assisted raise/lower and both have fore/aft adjustment. Settings are then fixed using over-center cam locks vs. threaded adjustment bolts. If you've been frustrated by the time it takes to screw/tighten down settings when setting up a rider, you'll love how quick and simple these are to use. The handlebars have a very refined/substantial/solid feel to them and include two water bottle holders. The assist from the gas struts (similar to what helps lift the hood or tailgate on your car) had me changing their height easily, even while in the riding position 🙂

In the quest to accommodate a wide variety of people, the handlebars extent outward as you raise them up (think Keiser M3) and they begin very low. I typically ride any IC with the bars all the way down and I needed to raise them to get comfortably setup on the IC7.

The power console (self-powered = no batteries) provides the expected rider metrics for watts, RPM, distance and HR if you're wearing a chest strap. And the unexpected - a resistance level indication and very cool LED lights that change colors based a participants‘ WattRate® (power) or heart rate and the training parameters set by the Coach By Color® training system. More on the console, the Coach By Color® system and how they get those lights to change correctly for each rider coming in a separate post.

One feature not included was a stage or lap button to measure intervals - but it will shortly. In a followup email from Bernd Pürschel - ICG's CEO and lead engineer, Bernd offered that they will be including this function in the near future.

Measured Power Using Optical Sensors

With multiple manufacturers offering power/watts, any comparative discussion between brands nearly always comes down to two simple questions;

- How accurate is the wattage displayed?

- Is that wattage consistent (feels the same) from bike to bike?

The claimed accuracy of the IC7 is +/- 1% which to me is saying the wattage displayed is nearly perfect.

Is that possible?

I had a long conversation with Bernd to understand where his confidence about accuracy and consistency of power come from. I wanted to learn specifically how torque is measured and displayed on the IC7's console. You no doubt understand that power/watts is equal to the twisting force (torque) a rider applies to the pedals... multiplied by the speed (RPM) in which the power is applied. Measuring the RPM side is easy, you just count the number of revolutions. Measuring the torque is the hard (and expensive) part of any power meter; indoors or out.

The accuracy, Bernd explained, comes from the use of an Optical Torque Sensor that forms the intermediate shaft in the drive train shown here in this photo of an IC7 going through long-term reliability testing.

Pedals turn the large sprocket and the toothed belt turns the intermediate shaft that doubles as the optical torque sensor.

To measure torque, something needs to twist or deflect and then have a sensor in place to measure tiny amounts of twist or deflection. In the bicycle world, strain gauges installed in the; pedals, rear hub, bottom bracket or crankarms are used the measure deflection caused by the rider pushing the pedals, that is resisted by the tire's contact with the ground. The FreeMotion S11.9 uses a strain gauge attached to the left side crankarm and the Blade Ion uses a strain gauge in the arm the holds the brake pad in place.

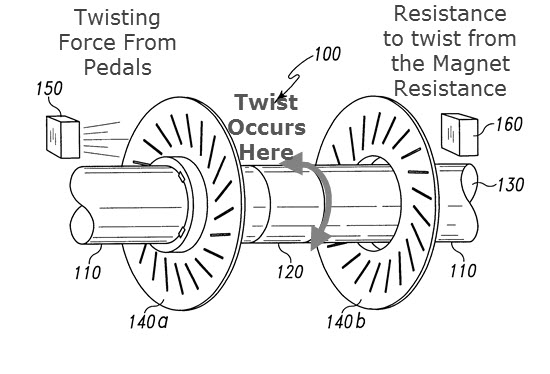

Instead of using strain gauges to measure torque, the IC7 measures the amount of twist that occurs in the intermediate shaft, using light that passes through a series of little windows on either end of the intermediate shaft. I found this drawing that may help to show what's happening down there.

Measuring your awesome amount of torque using light 🙂

Here's a very simplistic explanation of how this works:

In its rested state, the little slots in the disks on either end of the shaft line up perfectly. Light shown (fig 150) from one end will pass easily between the slots and out the other side to a sensor (fig 160). Now imagine what would happen if you twisted the shaft - the slots are no longer lined up, right? Using fancy electronics it is possible to measure this twist with incredible precision by sensing changes in the amount of light passing from one site to the other.

Now if you know with certainty what amount of force twists the shaft "X" amount, you have the makings of a very accurate method of measuring torque. Bernd assured me that the intermediate shaft is build using very special (and expensive) German steel, which results the complete system having a margin of claimed error of just +/- 1%. It's important to note that ICG didn't invent using Optical Sensors to measure torque. They've been used for years in precision machines that require a very high degree of accuracy.

Here's a computer simulation showing details of the inner workings.

So how about bike to bike?

The fundamental problem I see on our classes where we've introduced power, is a lack of trust from both Instructors and riders in the wattage being displayed. Consistency between cycles is (to me) more important than if they're super accurate. I don't care what I see as my FTP wattage, as long as that level of effort feels the same regardless of which of the Indoor Cycles in our studio I choose to ride. Bernd feels they have that solved through a simple method of calibrating the 100 position resistance control with the magnet holder. It's beyond me to explain how it works in words - hopefully they'll create a video that shows the procedure.

Next up - Coach by Color® and how it will help communicate to you (the Instructor), that everyone has heard and understood your intensity cues.

Podcast: Play in new window | Download

Originally posted 2014-04-08 11:55:44.

Would like to know how the colors work if using heart rate monitor. What color should display at each heart rate level would vary by a rider’s age group.

If it just uses one set of metrics for all riders does not seem very useful.

Once I understand how this works it will finalize my decision on whether to purchase the bike or not.

Bruce the concept of age related heart rate zones has been thoroughly discredited = everyone in your room can work together… after completing a short threshold assessment that is conducted as part of the class.

The use of Power/Watts has really replaced (superseded) Heart Rate as a measure of intensity – which is all that a HR monitor does anyway.

Hi I would like to know does the IC7 support garmin HR chest stratps?

Hi Ferdie,

The current IC7 computer console only picks up Polar HRMs and MyZones HRMs. We have a new computer coming out in August/September that will pick all monitors (like Garmin). The new console will have Bluetooth, Ant-+ and wifi capabilities. You will even be able to pair your Garmin power meter (or others with BT) to the console and walk away from your ride on the IC7 with your power results.

Happy riding!!!!

Thanks for jumping in here Mike and answering her question!

John,

We bought Stages bikes 3 months ago and have been struggling with the inconsistency in readings between bikes.

Here is a direct quote from Stages on why their bikes will never read consistently between bikes:

“There are many variables that will effect what that starting resistance is. The power meter is accurate and consistent in measuring the actual power. However, we do not make any claims that the actual starting resistance of each bike is going to be exactly the same. ”

Appears they have not figured out this ‘calibration’ thing yet. Maybe you could have your Kaiser contact give the Stages team a hand with this…

#IwouldnotbeleiveitifIdidn’tseeitmyself!

Chris, you have a great point with regard to inconsistency.

The more I am told that I am the ONLY indoor cycling studio/program experiencing power meter inconsistency … the more I think … “NO WAY.”

No way am I the ONLY indoor cycling studio/program experiencing inconsistent power readings.

I am quite possibly however … the ONLY person CRAZY enough to learn, observe, document, and recognize patterns in power meters that nobody else has the patience to learn, observe, document, or recognize.

#iknowpower

Karen

Anyone know how the IC7 stands up to Keiser? Just curious if anyone has any experience with a comparison between the two. We are considering switching from Keiser to IC7, but I am apprehensive when we have overall been happy with Keiser

The IC7 computer is better than Keiser computer

So is the ANT+/Wifi/Bluetooth version released yet? And are the different communication protocols working? If yes, where can I purchase it and does it come fully documented regarding it’s interface (for communication)?

Hi,

I’m wondering how to tell the difference between new console? Does new console come out yet? Thanks!

Hi John,

Great article. I have a question about IC7 FTW test.

I was doing a spinning class for the last year 3-4 times per week.

I did the 20 min FTW test and I got: 190. That is much lower what I do in my normal class without any problem and following the instructor color class in 250 FTW setup .

I tried doing the test using a different bike, different RPM and different initial level/resistance and always getting the same number. I think the initial resistance is the tricky part because I was not able to start with highest resistance more than 25-26 and keep in my target (watts + color)

After reading your article I was thinking that the torque sensor is not measuring the power correctly because I can do the test almost not putting pressure on the pedal.

Thanks so much.

I understand how the power output can be accurately determined, but I’m not clear on how the calories burned are calculated which obviously must depend on the spinner’s muscle efficiency. How does IC7 use age, weight, weekly cardio training time, and FTW level to estimate this? Does FTW level even enter into the calorie calculation?

Does the IC5 work with this Garmin Heart Rate Monitor: https://www.amazon.com/gp/product/B000UOD5QM/ ?

I am currently shopping. My gym is this the matrix IC7, at least, that’s what it looks like. Do you know a comparison between this brand and the life fitness IC7? They look very similar although not identical. In reading the specs they also sound similar, although I am not an expert at bikes so I may be missing some nuances.

Sorry Lori – I don’t know much about the Life Fitness bike.

John, how have these bikes held up for you? I am thinking about buying a used IC7 directly from LifeFitness. My gym has these and I love using them so much that I’d like to have one at home instead of having to go to the gym to use it. I’m concerned about longevity as well as maintenance though. How has your experience been with them so far over the last few years?

Hey,

that’s a super cool explanation of the IC7.

But what I noticed is that the speed of the disk does not match the speed on the computer of the IC7.

I once attached a magnet to the disc and measured it with a wheel sensor. The disc is 132cm that’s right but my measured speed is almost twice that of the IC7.

Can you say or explain something about this?

Sincerely yours

Martin k.