I had the privilege of visiting the Stages Cycling HQ and factory in Boulder Colorado with my buddy Randy Erwin. Director of Indoor Cycling education Cameron Chinatti, along with Stages vice president Pat Warner, were our tour guides. We spent a fascinating couple of hours learning exactly what goes into building the Stages single side crank arm power meter used on the new Stages SC3 Indoor Cycle and available for most road/mountain bicycles.

You know these people are cyclists the moment you walk into the place. Everywhere you look there are bicycles; tucked into every corner, hanging from the ceiling, along every wall - heck, their conference room has probably the coolest table I've ever seen. Instead of legs, the table top is supported by a pair of 70's vintage Schwinn Sting-Ray bicycles.

Cameron explained the hiring process, "you pretty much have to be a passionate cyclist to even be considered... many of these guys have been riding buddies for years." And I'll add that these "cyclists" are also some of the most brilliant people I've ever met 🙂

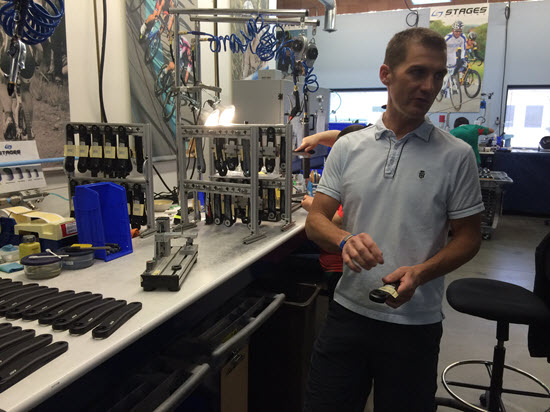

Cameron explaining all the cool features of the Stages SC3 to cyclist Randy Erwin

Cameron met Randy and me and our tour started in their official "training room" except it won't be for long. Stages is growing so fast that half of this room has been taken over by manufacturing stations. My friend Randy was very interested in the new SC3 because the Westminster, CO Life Time Fitness (where he's a member) will be the very first location to get these new cycles. Now if we could get Dennis Mellon in there as an instructor...

New power meters being installed and tested - this is super technical stuff.

Early in the our factory tour, I asked Pat; "why aren't your power meters built in Asia, like most other technology companies?" His responses made perfect sense to me; "there are multiple reasons actually." "Stages has become the leading provider of bicycle power meters, after only a few years. We can't afford any preventable issues when it comes to quality or availability. It's critically important that we control the quality of these power meters... we can't if we're dependent on a third party supplier's factory, regardless of where it's located."

Pat explained how keeping everything in-house provided a solution to a unique challenge they faced. "We manufacture power meters for 16 different model bicycle crank arms, from major suppliers (Shimano, SRAM, Cannondale and FSA) plus the power meter for the SC3 Indoor Cycle. Bicycle cranks aren't made just one size. Multiply each model bicycle crank by the four or more available crank arm lengths and we have to stock over 60 part numbers. Sure, 172.5 is the most common size for a road bike, but how many of each should we be building? The lead time for overseas manufacturers is measured in months - customer's won't accept waiting that long. We have thousands of stock crank arms on hand and we're setup to quickly change production. So if we receive an order for an out of stock power meter, we can normally build one and ship it within a few days!"

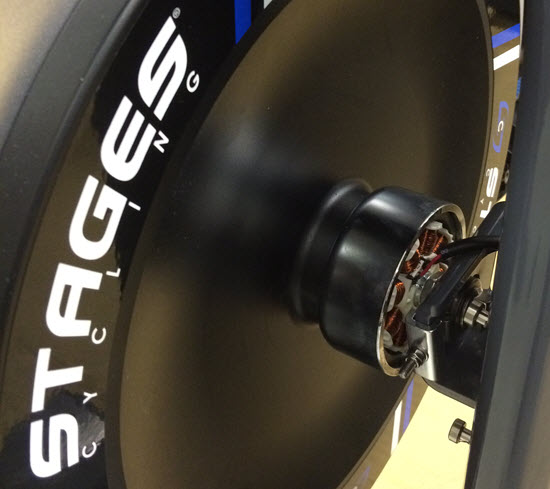

Pat Warner explaining the complicated process that attaches the power meter to the crank arm.

Every power meter is checked for proper calibration and the results captured using a iPad with custom software that's developed in-house too!

The Stages SC3 is build by Giant Bicycles in Taiwan - Pat told me,"those Giant guys are experts at mass producing high quality bicycles and fitness equipment, so we leave that part to the experts. We still produce the SC3's power meter here in Boulder and then ship them out for installation on the cycle."

Stages has a separate facility, near their main offices, that's use for product endurance and destructive testing. We just missed the completion of a test rig that repeatably pressed down on a handle bar, tens of thousands of times without any failure.

Want to know how long the drive train will last pedaling at a continuous 360 watts? This video shows the test rig that pedals 24/7 for weeks at a time. Not only are they watching to see if something will break, or wear out, but they also record the actual power readings vs what they know their electric motor is pushing.

Quality control - Early production Stages SC3 cycles are unboxed and checked for any defects.

Feel free to leave the lights on! There's the battery charger for the Stages SC3 power meter.